- About the Department

- Vision & Mission

- PEO, PO, PSO, & CO

- Faculty Members

- Advisory Committee

- IMPaCT Lab

- SPAN

- University Rank Holders/Toppers

- Placement

- Achievements

- Notable Alumni

- Association & Activities

- Workshops/Seminars

- Publications

- Department Library

- Lab Facilities

- Mentoring

- MoUs & Industry Connects

- Funded Research Project

Workshops & Seminars

Workshops and Seminars 2023 & 2024

Two-Day MATLAB Workshop on Simulation and Computational Thinking

The Department of Electronics at Toc H Institute of Science and Technology, in collaboration with MathWorks and CoreEL Technologies, organized a two-day MATLAB workshop titled “A Hands-On Journey through Simulation and Computational Thinking” for S1 ECE students on 11th November 2025. The workshop was designed to provide students with practical exposure to simulation tools, computational problem-solving, and real-time engineering applications using MATLAB. The sessions were expertly led by Mr. Dhanoop Dhanapal, Application Engineer at CoreEL Technologies India Pvt. Ltd., who guided the participants through fundamental and advanced concepts with live demonstrations and interactive activities.

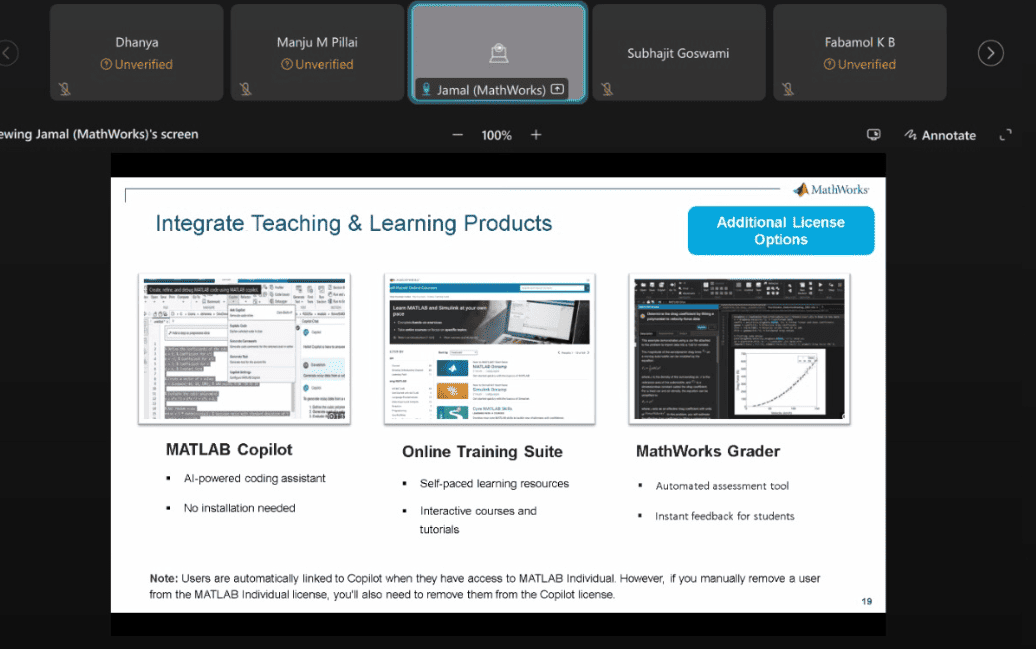

Department-Level Technical Collaboration -Meeting with MathWorks

An online technical session MATLAB on-board to introduce the features of the campus wide license was conducted on 10th October 2025. The session was led by Mr. Jamal from MathWorks and attended by (Prof.) Dr. Deepa Elizabeth George , Asst. Prof. Dhanya R Asst. Prof. Sheethal Ann Varghese , and Lab Instructors Ms. Manju M. Pillai and Ms. Nithya. The discussion focused on academic collaboration, technical enrichment, and the integration of MathWorks tools in teaching and research activities.

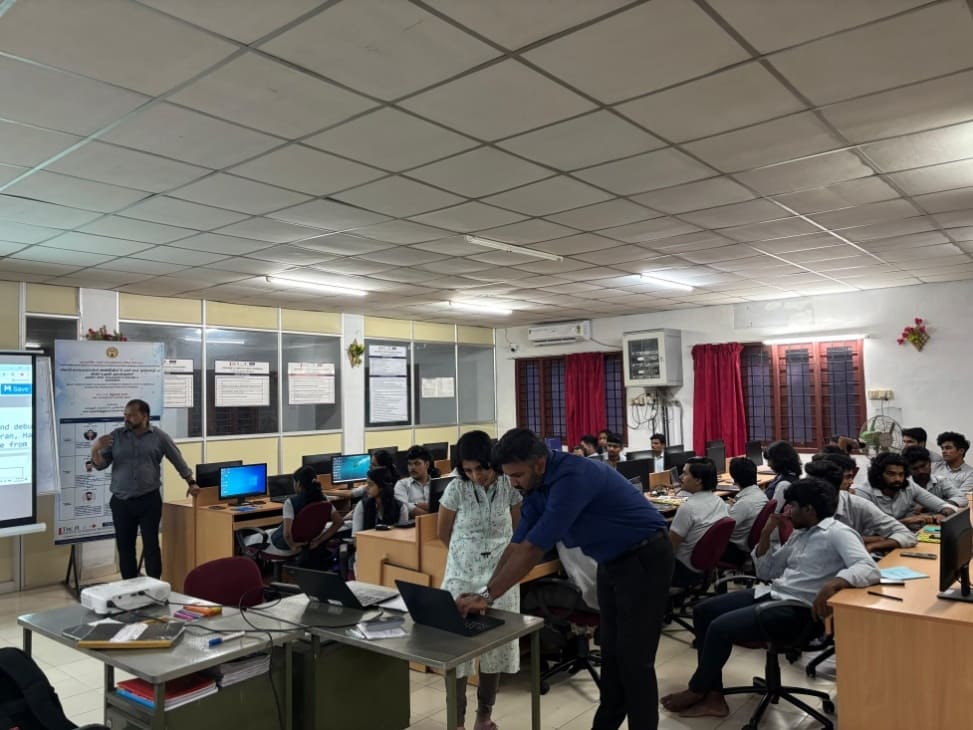

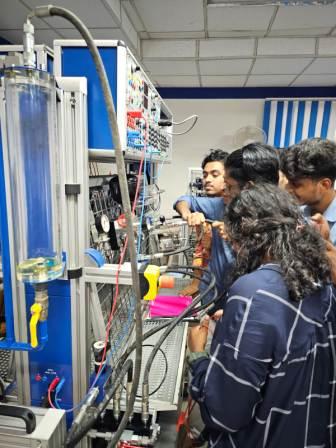

Industry-Integrated Automation Workshop by CodX Systems

A three-day Industrial Control and Automation workshop was conducted by CodX Systems in association with SPAN at the Department of ECE, Toc H Institute of Science and Technology. The workshop was held on the 2nd, 5th, and 7th of July 2025.and attended by students of second year ECE . The workshop provided hands-on training using industry-grade tools rather than standard academic kits. Students received practical exposure to PLC wiring and programming, actuators, pneumatics, HMI development, and safety systems. The sessions were led by Akshay Kannan and Noble Jacob, 2020 Robotics and Automation alumni of TIST. Akshay is currently working as an Automation Engineer at Nest SFO Technologies, while Noble is associated with Brainwired, a tech startup in the agri-tech domain.

Students Gain Exposure to Atmospheric Radar Research

Students of Semester 5, Electronics and Communication Engineering, from Toc H Institute of Science and Technology, Arakkunnam, successfully completed a short-term internship titled “Radar Meteorology and Atmospheric Data Processing” at the Advanced Centre for Atmospheric Radar Research (ACARR), CUSAT. The internship was conducted from July 1 to July 5, 2025.. The internship provided hands-on exposure to atmospheric radar systems and data processing techniques, enhancing the student’s understanding of meteorological data analysis.

Workshop on UAV Technologies

Fuselage Innovations Pvt. Ltd. conducted a three-day workshop on UAV technologies for S6 ECE students from February 24th to 27th, 2025. The session offered valuable insights into UAV advancements, applications, and industry trends, along with hands-on exposure to UAV systems. Students actively engaged in various aspects of the workshop, including UAV design, construction, functionality, and real-world applications. Prithvi Ullas, a 2023 Robotics and Automation alumnus and Junior UAV Engineer at Fuselage Innovations, was part of the team leading the sessions. The workshop was organized by the SPAN Cell.

Electronics Made EZ: Bridging Theory and Practice in Analog Electronics

An online workshop titled “Electronics Made EZ” was conducted by the Skill Planning and Acquisition Cell on 10th and 11th February, 2025. The workshop was attended by students from S2 ECE, providing them with fundamental knowledge and practical exposure to electronics concepts in Analog Electronics in an engaging and accessible manner.

Hands-On Drone Workshop: Exploring UAV Technology

A three-day hands-on workshop on Drones was conducted from January 30 to February 1, 2025, led by Anfil Shajo, an alumnus of the 2020 Robotics and Automation batch and his team from DC Robotics. The workshop provided participants with in-depth knowledge of drone technology, including assembly, programming, and real-world applications. Students from S2 Robotics and Automation (RA) and Electronics and Communication Engineering (ECE) actively participated, gaining valuable hands-on experience in UAV technology and operations.

Mastering Python: 5-Day Intensive Training by Aesthetix for TIST ECE Students

From December 9th to 13th, 2024, Aesthetix conducted a comprehensive 5-day Python training program for final-year Electronics and Communication Engineering (ECE) students at TIST.The training focused on building a solid foundation in Python programming, covering core concepts, advanced techniques, and practical applications. Through hands-on exercises, live demonstrations, and real-world examples, students gained valuable skills to enhance their coding proficiency, preparing them for academic projects and future career opportunities. The program was a significant step toward empowering students with essential programming expertise

TIST ECE Department and SPAN Present 2-Day Embedded IoT Workshop by Srishti Robotics

A two-day workshop on Embedded IoT, organized by the Skill Planning and Acquisition Cell (SPAN), was conducted by Srishti Robotics at Toc H Institute of Science and Technology (TIST) on December 18th and 19th, 2024, for Electronics and Communication Engineering students. The workshop provided students with vital knowledge and hands-on experience, proving instrumental for their Embedded IoT coursework and project.

Online Session on “Startup Success – Navigating the Path from Idea to Impact”

TIST Institution Innovation Council (IIC), in association with the Department of Electronics and Communication, the Department of Robotics and Automation, and TIST IEDC, successfully organized an online session titled “Startup Success – Navigating the Path from Idea to Impact” on November 29, 2024.

The session featured Mr. Sreeshankar S Nair, Co-Founder & CEO of Brain wired, as the keynote speaker. He shared valuable insights into the Startup ecosystem, emphasizing strategies to transform ideas into impactful ventures. The session was attended by students of first year ECE .

The event served as an inspiring platform for aspiring entrepreneurs and innovators, reflecting TIST’s commitment to fostering innovation and entrepreneurship among students and faculty.

Department of ECE Participates in MatTech 2024

The Department of Electronics and Communication Engineering (ECE) actively participated in MatTech 2024, an event organized by the Department of Mechanical Engineering in collaboration with ISHRAE, Kochi Chapter, on November 29, 2024. The event was attended by Dr,Deepa Elizabeth George and Asst Prof Renjith P.K of ECE Department. The event provided an excellent platform for interdisciplinary learning, fostering collaboration between engineering disciplines. The Department of ECE’s participation underscored its commitment to engaging in innovative events that promote knowledge sharing and industry-academia interaction

Useless Project Make-a-thon: “A Creative Coding Revolution at TIST”

The Useless Project Make-a-thon, organized by Tinker Hub in collaboration with Tinker Hub Toc H, was an exciting 18-hour hackathon held at the Toc H Institute of Science and Technology (TIST) in Kerala. Spanning over 30 venues and bringing together over 2500 creative minds, the event aimed to inspire innovation and push the boundaries of creativity. Participants were encouraged to either code something “useless” or bring imaginative ideas to life. Held from 2:00 PM on November 2nd to 8:00 AM on November 3rd, 2024, at the Ramanujan Hall, TIST, the event offered a dynamic platform for collaboration and idea exploration. Aiswarya Chandrashekaran, S5 ECE batch, served as the TinkerHub college lead, playing a key role in organizing and leading the event at the TIST venue. Bhavana V. Nair, Abhijith Sivan, and Aaron Bejy Mathew, all from the S5 ECE batch, volunteered for the event.

Seminar on Geo Spatial Technology in Disaster Risk Mapping

On 9th September 2024, the Department of Electronics at Toc H Institute of Science and Technology hosted a seminar on “Geospatial Technology in Disaster Risk Mapping”, in collaboration with the Directorate of Technical Education, Kerala, as part of UDYAMA 1.0. led by guest speaker Dr. Girish Gopinath, Professor and Head of Climate Variability and Disaster Management at KUFOS. The seminar explored the crucial role of geospatial technology in enhancing disaster risk management. With a diverse audience of students, faculty, and professionals, the event fostered discussions on the challenges of disaster management and innovative solutions through geospatial data. This initiative not only enriched participants’ understanding but also aimed to build future partnerships between academia and industry, promoting collaborative approaches to real-world disaster management challenges.

Industrial Training on Digital Design and Verification using Cadence Tool by ENTUPLE TECHNOLOGIES

The successful completion of Industrial Training on Digital Design and Verification using Cadence Tool by ENTUPLE TECHNOLOGIES from 22nd July 2024 to 26th July 2024, mark the beginning of an ever – going learning experience of converting ideas and concepts into practical system. It was a five-day session, covering fundamentals of ASIC flow ,FPGA flow and Verilog constructs, combinational circuit design using Verilog, sequential circuit design using Verilog and modelling of a protocol state machine, and writing Test bench for a given design. The training session gave a hands-on experience on designing and testing of SoC & integrated circuits (ICs) using CADENCE TOOL.

TRAINING AND INTERNSHIP AT BOSCH REXROTH-GPTCK CENTRE OF COMPETENCE IN AUTOMATION TECHNOLOGIES

Bosch Rexroth – GPTCK, Centre of Competence in Automation Technologies held a training and internship for the fifth and seventh semester B.Tech Robotics and Automation students of Toc H Institute of Science and Technology from 11th September to 16th September 2023.

Topics covered in the PLC (Programmable Logic Controller) Lab included the fundamental components, software used and Bosch PLC. Circuit logic for PLC applicationslike sustained PLC circuit, lighting control and motor control were designed and tested. The training also covered fundamentals of Industrial Automation – drives, controllers, sensors. In the Sensors Lab, experiments with various sensors – inductive, capacitive, magnetic, photoelectric, etc. were conducted. Lift logic was executed on Bosch PLC – PLC circuit to move from each floor to all other floors in a 3 level lift.

Various aspects of hydraulics and pneumatics were covered. The theory and practice on hydraulic and pneumatic systems imparted practical knowledge in an effective manner. Control of extension and retraction of a cylinder was done directly and indirectly using directional control valves. In the Applications Lab, integration of all systems was described. A mini assembly line model involving hydraulics and pneumatics controlled by PLC was studied.

INDUSTRIAL TRAINING ON PLC, VFD and SCADA

A two-day Industrial Training Program on PLC, VFD and SCADA was conducted by Mr. S. Raja and Mr. Kesav of Silicon Systems, Coimbatore on 4.1.2024 to 5.1.2024for the faculty of the Department of Electronics (ECE and RA).The program covered PLC hardware and programming. Ladder Logic Programming for applications targeted to Delta PLC AS218TX were developed in ISPSoft software and tested in online mode. These programs were then downloaded to the PLC to implement the application in the PLC.

Training on the Variable Frequency Drive VFD interfaced with DVP14SS2 Delta PLC was also done. Various modes by which the speed of a 3 phase induction motor could be controlled by the VFD were implemented.Interfacing of Human Machine Interface HMI with the AS218TX PLC using DoPSoft HMI Tool was also covered through various hands on applications. Lastly, SCADA software DIAView Development and DIAView Runtime were used to acquire and analyze real-time data and to control the PLC by giving various inputs.

FACULTY DEVELOPMENT PROGRAM ON TEXAS INSTRUMENTS TMS320C6748 FIXED AND FLOATING POINT DSP

An FDP was conducted to train faculty to use the TMS320C6748 DSP Processor on 10.1.2024 for various applications including filtering, audio acquisition and real-time signal processing. The TMS320C6748 fixed and floating point DSP is a low-power applications processor based on C674x DSP core. Code Composer Studio which is an integrated development environment (IDE) for TI’s controllers and processors was used to develop and debug these applications.