Workshops & Seminars

Workshops & Seminars 2024-2025

Participation in Bridge-IT :National-Level Hackathon at TIST – TECHSHILA ’25

Two teams from S4 RA participated in the “Bridge It” Hackathon at TIST – TECHSHILA ’25 on 1st February 2025. Team 1, consisting of Niharika Madhu, Sherin Shanawaz, Neeraj.P.Raju, and SaranKumar.S, and Team 2, comprising Alwin Xavier, GladwinGeorge ,Jerint.P.Vinoj and Vansen Rowsh, showcased their creativity and engineering skills in designing and constructing truss bridges. Their active participation highlighted the spirit of innovation and teamwork, contributing to the success of the event

Attending Sessions at the Summit of the Future hosted by Jain University

The Summit of the Future, held at Jain (Deemed-to-be University) in Kochi from 25th January to 1st February, 2025, focused on innovation, entrepreneurship, sustainability, and education. The event gathered experts and academicians to discuss emerging trends., Swathy Satheesh, Assistant Professor, Robotics and Automation, and Dhanya R., Assistant Professor, Department of ECE, attended sessions, gaining insights into technological and academic advancements.

Workshop on UAV Technologies

Fuselage Innovations Pvt. Ltd, conducted a 3-day workshop on UAV technologies for the students of S6 RA on 24th to 27th February 2025. The session provided valuable insights into UAV advancements, applications, and industry trends, along with practical exposure to UAV systems. Students actively participated in the workshop which included UAV design, UAV building, functionality and real-world applications. Prithvi Ullas, a 2023 Robotics and Automation alumnus and Junior UAV Engineer at Fuselage Innovations was a part of the team that conducted the workshop.The workshop was conducted by the SPAN cell

Electronics Made EZ: Bridging Theory and Practice in Analog Electronics

An online workshop titled “Electronics Made EZ” was conducted by the Skill Planning and Acquisition Cell on 10th and 11th February, 2025. The workshop was attended by students from S2 RA, providing them with fundamental knowledge and practical exposure to electronics concepts in analog electronics in an engaging and accessible manner.

Alumni Interaction: Insights into Engineering Careers

An interactive session was held for S2 students of ECE &RA , featuring alumni Akshay Kannan (Automation Engineer, SFO Technologies) and Anfil Shajo (DC Robotics ), both from the 2020-2024 Robotics and Automation batch. Akshay shared his experiences in project competitions, internships, and his work on developing and deploying a Robotic Welding Cell at SFO Technologies. Anfil highlighted the importance of hands-on experience, participation in external events, and the vast opportunities available for skilled engineers. The session provided valuable insights into industry trends and career pathways for aspiring engineers.

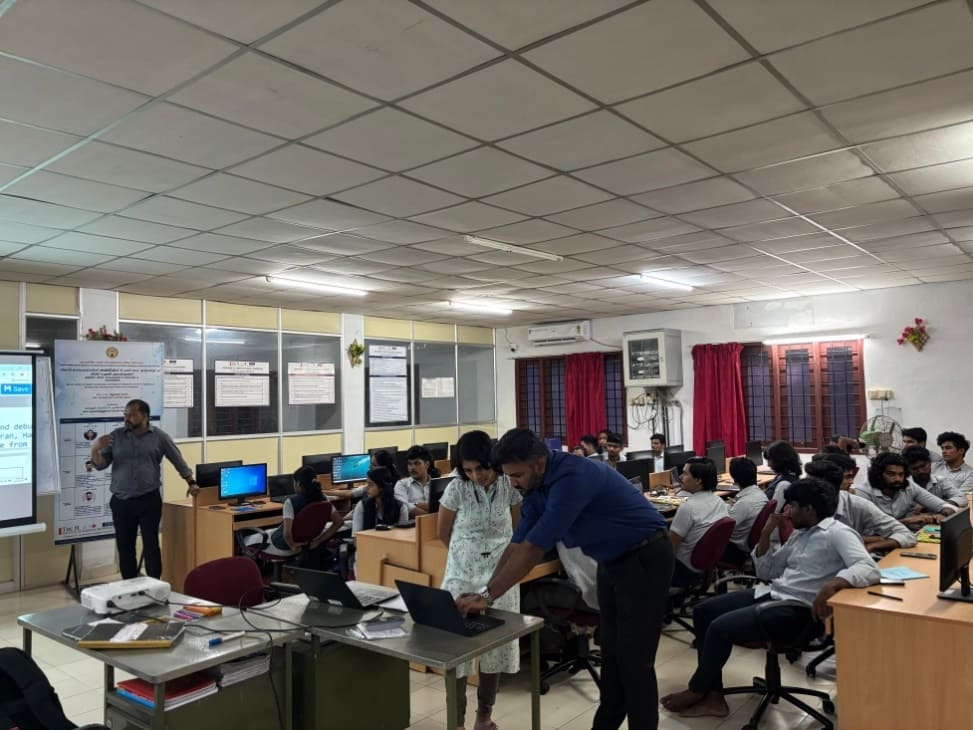

PLC Workshop: Mastering Automation

A full-day hands-on PLC Workshop was held on January 31, 2025, at the Automation Lab, led by Asst. Prof. Swathy Satheesh (Dept. of Robotics and Automation, IEEE SPS chapter Advisor).Participants explored PLC fundamentals, ladder logic programming, and real-time applications, gaining hands-on experience in industrial automation and troubleshooting. Jointly organized by ELECTRAA, the workshop saw enthusiastic participation from students across ECE, Robotics & Automation, EEE, and Electronics & Computer Engineering, enhancing their industry-relevant automation skills.

Hands-On Drone Workshop: Exploring UAV Technology

A three-day hands-on workshop on Drones was conducted from January 30 to February 1, 2025, led by Anfil Shajo, an alumnus of the 2020 Robotics and Automation batch and his team from DC Robotics. The workshop provided participants with in-depth knowledge of drone technology, including assembly, programming, and real-world applications. Students from S2 Robotics and Automation (RA) and Electronics and Communication Engineering (ECE) actively participated, gaining valuable hands-on experience in UAV technology and operations.

Enhancing Coding Skills: 5-Day Python Training by Aesthetix

A 5-day Python training session was conducted by Aesthetix for final-year and Robotics and Automation (RA) students from 9th to 13th December 2024.The training program covered essential Python concepts, programming techniques, and real-world applications, with a focus on enhancing students’ coding skills for academic and professional success.

2-Day Workshop on Embedded IoT by Srishti Robotics at TIST

A two-day workshop on Embedded IoT, organized under the Skill Planning and Acquisition Cell (SPAN), was held by Srishti Robotics at Toc H Institute of Science and Technology (TIST) on 18th and 19th December 2024 for students of S4 Robotics and Automation. The workshop aimed to equip students with essential knowledge and hands-on experience, proving highly beneficial for their Embedded IoT course, as well as mini and major projects. Participants were encouraged to fully leverage this valuable learning opportunity.

“Robotics and Automation Department Participates in MatTech 2024: Advancing Interdisciplinary Collaboration”

The Department of Robotics and Automation participated in MatTech 2024, organized by the Department of Mechanical Engineering in collaboration with ISHRAE, Kochi Chapter, on November 29, 2024. Represented by Dr. Deepa Elizabeth George and Asst. Prof. Mahesh C., the event fostered interdisciplinary learning and collaboration among engineering disciplines. The department’s involvement underscored its commitment to promoting innovation, knowledge sharing, and strengthening industry-academia connections..

Exploring AI Frontiers: Robotics and Automation Students at ICSET 2024 Workshop

On September 30, 2024, seventh-semester students from Robotics and Automation—Alwin Shibu, Sandeep Prakash, Azeem Bin Shiras, Niharika Madhu, Aswajith Kumar, and Saran Kumar—participated in a workshop titled “The Quantum Leap: AI and Beyond” at the International Conclave on Science, Engineering, and Technology held at the Adlux Convention Centre in Angamaly. The workshop offered an in-depth exploration of cutting-edge advancements in artificial intelligence and their implications for future technologies. Participants engaged with experts in the field, deepening their understanding of AI’s transformative potential and its integration with emerging technologies.

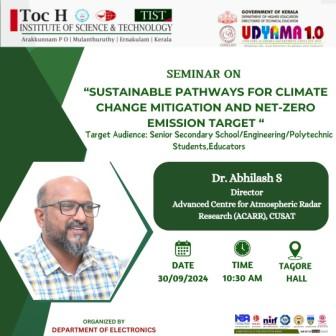

Seminar on Sustainable Pathways for Climate Change Mitigation and Net Zero Emission Targets

On September 30th, 2024, the Department of Robotics and Automation hosted a seminar titled “Sustainable Pathways for Climate Change Mitigation and Net Zero Emission Targets,” featuring Dr. S. Abhilash, Director of ACARR, CUSAT. The seminar, part of the Udhyama program, aimed to address pressing climate change challenges and explore innovative solutions for achieving net-zero emissions. Dr. Abhilash shared insights on sustainable practices and technologies that can be integrated into various sectors to mitigate climate impacts. The event encouraged active participation and discussions among students, faculty, and industry experts, fostering a collaborative approach to environmental sustainability and highlighting the critical role of emerging technologies in combating climate change.

INTERNSHIP AT BOSCH REXROTH-GPTCK CENTER OF COMPETENCE IN AUTOMATION TECHNOLOGIES

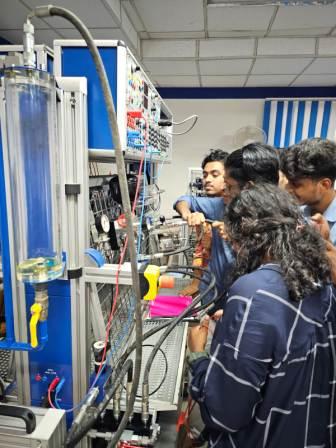

Bosch Rexroth – GPTCK, Centre of Competence in Automation Technologies held a training and internship for the fifth- semester B.Tech Robotics and Automation students of Toc H Institute of Science and Technology from 22nd July to 27th July 2024(6Day).

Topics covered in the PLC (Programmable Logic Controller) Lab included the fundamental components, software used, and Bosch PLC. Circuit logic for PLC applications like sustained PLC circuits, lighting control, and motor control were designed and tested. The training also covered fundamentals of industrial automation – drives, controllers, and sensors. In the Sensors Lab, experiments with various sensors – inductive, capacitive, magnetic, photoelectric, etc. were conducted. Lift logic was executed on Bosch PLC – PLC circuit to move from each floor to all other floors in a 3 level lift.

Various aspects of hydraulics and pneumatics were covered. The theory and practice on hydraulic and pneumatic systems impart practical knowledge in an effective manner. Control of extension and retraction of a cylinder was done directly and indirectly using directional control valves. In the Applications Lab, integration of all systems was described. A mini assembly line model involving hydraulics and pneumatics controlled by PLC was studied and visit a Application lab to familiarize the conveyar belt, mechanization, and automation.

Workshops & Seminars 2023-2024

TRAINING AND INTERNSHIP AT BOSCH REXROTH-GPTCK CENTRE OF COMPETENCE IN AUTOMATION TECHNOLOGIES

Bosch Rexroth – GPTCK, Centre of Competence in Automation Technologies held a training and internship for the fifth and seventh semester B.Tech Robotics and Automation students of Toc H Institute of Science and Technology from 11th September to 16th September 2023.

Topics covered in the PLC (Programmable Logic Controller) Lab included the fundamental components, software used and Bosch PLC. Circuit logic for PLC applicationslike sustained PLC circuit, lighting control and motor control were designed and tested. The training also covered fundamentals of Industrial Automation – drives, controllers, sensors. In the Sensors Lab, experiments with various sensors – inductive, capacitive, magnetic, photoelectric, etc. were conducted. Lift logic was executed on Bosch PLC – PLC circuit to move from each floor to all other floors in a 3 level lift.

Various aspects of hydraulics and pneumatics were covered. The theory and practice on hydraulic and pneumatic systems imparted practical knowledge in an effective manner. Control of extension and retraction of a cylinder was done directly and indirectly using directional control valves. In the Applications Lab, integration of all systems was described. A mini assembly line model involving hydraulics and pneumatics controlled by PLC was studied.A two-day Industrial Training Program was conducted by Mr. S. Raja and Mr. Kesav of Silicon Systems, Coimbatore for the faculty of the Department of Robotics and Automation. The program focused on PLC, VFD, and SCADA, covering both theoretical concepts and practical applications.

The training delved into PLC hardware and programming, with a specific emphasis on developing Ladder Logic Programs for Delta PLC AS218TX using ISP Soft software. These programs were created and tested in online mode before being downloaded to the PLC for practical implementation.

Additionally, the program included hands-on training on Variable Frequency Drives (VFD) interfaced with DVP14SS2 Delta PLC. Various modes for controlling the speed of a 3-phase induction motor using VFD were explored and implemented.

The participants were also exposed to the interfacing of Human Machine Interface (HMI) with AS218TX PLC using the DoPSoft HMI Tool. This practical aspect allowed the participants to gain valuable insights into real-world applications.

The training concluded with a session on SCADA software, where DIAView Development and DIAView Runtime were utilized. Participants learned how to acquire and analyze real-time data and control the PLC by providing various inputs. Overall, the program provided a comprehensive understanding of PLC, VFD, and SCADA technologies through hands-on experience and practical applications.

FACULTY DEVELOPMENT PROGRAM ON TEXAS INSTRUMENTS TMS320C6748 FIXED AND FLOATING POINT DSP

An FDP was conducted to train faculty to use the TMS320C6748 DSP Processor on 10.1.2024 for various applications including filtering, audio acquisition and real-time signal processing. The TMS320C6748 fixed and floating point DSP is a low-power applications processor based on C674x DSP core. Code Composer Studio which is an integrated development environment (IDE) for TI’s controllers and processors was used to develop and debug these applications.

Internship at BOSCH REXROTH, Centre of Excellence, GPTC Kalamassery

B.Tech Robotics and Automation students (82 Students) attended the internship provided by BOSCH REXROTH Centre of Excellence as part of MOU with GPTC Kalamasserry, Kochi from 11th to 16th September along with Er. Nandu Gopakumar G (Toch RA Faculty). 42 Students from S5 (RA 2021 Batch) and 40 Students from S7 (RA 2020 Batch) attended the Internship Programme.

Bosch Rexroth, a subsidiary of Robert Bosch GmbH, specialises in drive and control tech for global industries like automation, hydraulics, industrial automation, mobile machinery, factory automation, and renewable energy. They excel in robotics, and IoT solutions, and have a worldwide presence, driving innovation, sustainability, and productivity across diverse sectors.

The session started at 9:30 AM and ended at 4:30 PM. The six days training programme helped the students in gaining an effective understanding and knowledge in the areas of Hydraulics, Electro-Hydraulics, Pneumatic, Electro-Pneumatic, Various Sensors, PLC Programming and Applications Lab.

Pneumatic

Workshops & Seminars 2022-2023

Workshop on Aerial Robotics & Drone Expo at Jawahar Navodaya Vidyalaya,Chennithala

A Workshop on ” Aerial Robotics and Drone Expo, was conducted at Jawahar Navodaya Vidyalaya, Chennithala on 10 th March ,2023 by Mr.Anfil Shajo , Third year B.Tech Robotics and Automation, Toc H Institute of Science and Technology as a part of Vigyan Jyothi Programme launched by the Department of Science and Technology (DST) in 2020. Vigyan Jyoti is a unique programme for meritorious girls students with the aim to address the underrepresentation of women in different fields of Science, Technology, Engineering and Mathematics (STEM) in the country. The workshop was jointly organized by the Department of Electronics, TIST and IEEE RAS chapter Toc H SB with Cochin University of Science and Technology as the Knowledge Partner.